1. Introduction of the bag filter in effect

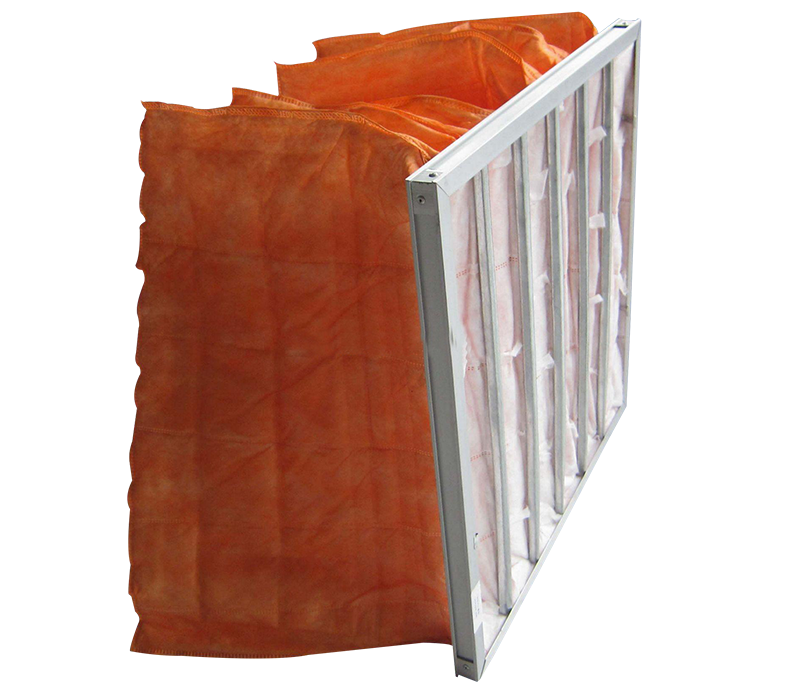

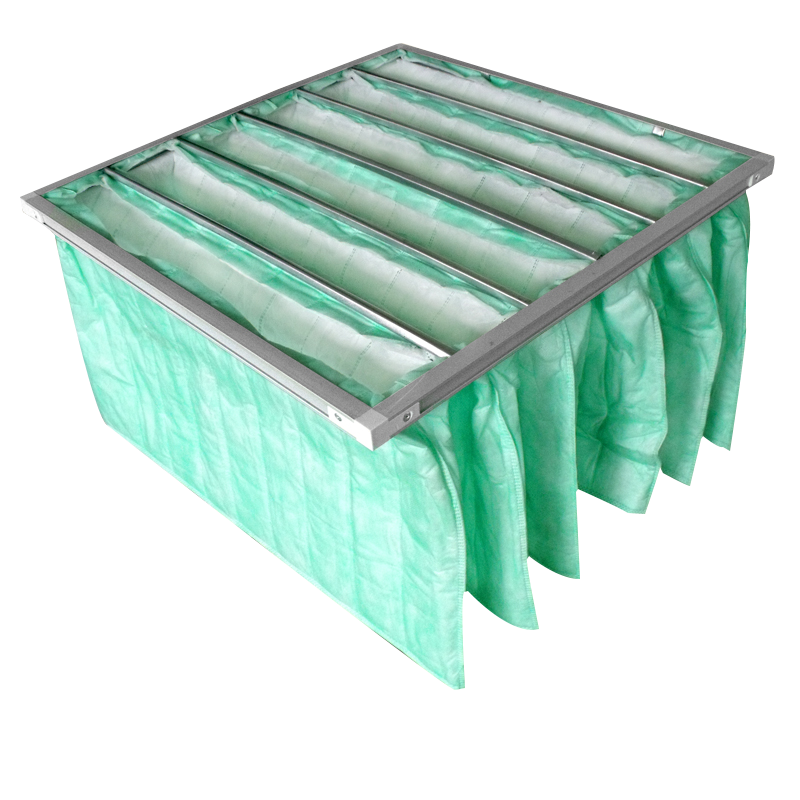

In the effective bag filter using high-quality chemical fiber non-woven filter effective filter area is large, mainly used for filtering more than 5μm dust particles, with dust capacity, resistance, small ventilation, etc., the framework and support frame can be reused , Replace the filter only need to replace the filter bag, and convenient, greatly reduce the operating costs. In the efficiency of the filter bag and box, modular and so on.

2, the effect of bag filter for the occasion

In the bag filter widely used in electronics, pharmaceutical, medical, food and other industries filtration system, is the best structure of the current efficiency filter. In the effect of bag filter equipment conditions 1. Temperature: -10 ~ ~ 80 ℃; 2 Humidity: ≤ 80%, slightly acidic alkaline air filter.

3 in the effectiveness of bag filter five characteristics

Large air volume, low resistance, stable performance, cheap, versatility.

1. washable

Savings of users want the filter to be cleaned and reused. The company's bag filter to meet this requirement. Some users have cleaned a filter several times, the filter life of up to one year.

2. Resistance is small

Special chemical fiber filter, a reasonable structure, so that the bag filter resistance to a minimum level.

3. Stable performance

The company's production bag filter in the chemical fiber filter on the static electricity, filtration indicators will not be due to static temporarily enhanced ingredients. Only the filter is not damaged, cleaning efficiency after cleaning as ever.

4. Strong versatility

The structure and size of the bag filter are unified with the international bag filter. Therefore, it is suitable for most central air conditioning and centralized ventilation systems.

5. Unique structure

Frame with special aluminum or galvanized sheet frame, easy to fully recover, use, high-quality μ-type aluminum alloy pressure, so that the structure of low resistance bag, long service life.

4. In effect bag filter efficiency types

G3, G4 - F5, F6, F7, F8, F9, for different occasions.

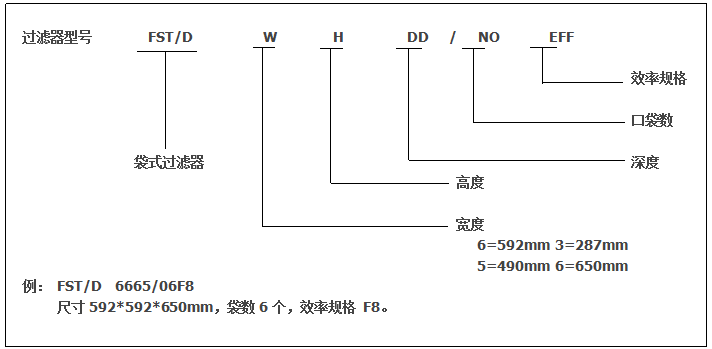

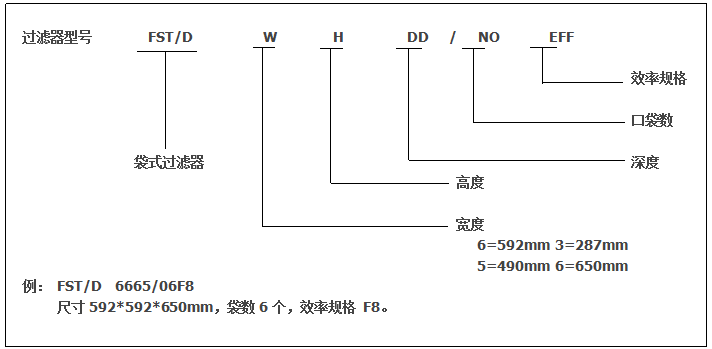

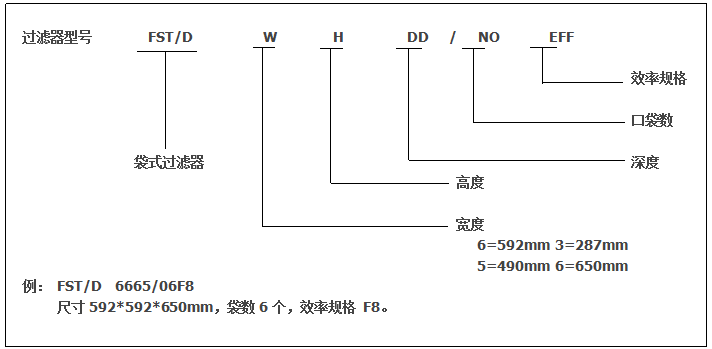

5. In effect bag filter type read ru le

6. In effect bag filter model specifications

| 型号 |

外型尺寸(mm) w宽*H高*D深 |

初阻力/风量(中间值为额定风量)Pa/M³h |

过滤效率(%) (比色法) |

袋数(个) |

| FST/D6665-F8 |

592*259*650 |

100/2500 145/3600 225/5000 |

95 |

≤10 |

| FST/D6665-F8 |

592*592*550 |

105/2500 145/3600 240/5000 |

95 |

| FST/D6665-F8 |

287*592*650 |

90/1250 130/1800 210/5000 |

95 |

| FST/D6665-F8 |

287*592*550 |

90/1250 130/1800 210/5000 |

95 |

| FST/D6665-F7 |

592*592*650 |

65/2500 100/3600 165/5000 |

85 |

| FST/D6665-F7 |

287*592*650 |

65/1250 100/1800 165/2500 |

85 |

| FST/D6665-F6 |

592*592*650 |

45/2500 70/3600 110/5000 |

65 |

| FST/D6665-F5 |

592*592*650 |

45/2500 75/3600 115/5000 |

60 |

| FST/D6665-F5 |

592*592*550 |

50/2500 76/3600 120/5000 |

65 |

7. Efficiency bag filter efficiency specifications

F5 (45%), F6 (95%), F7 (95%), F9 (95%), F9 (98%);

Frame thickness series: 21mm, 25mm, etc .;

8. In the effect of bag filter

1. Regularly check the filter inlet surface with or without debris jam, the filter surface with or without damage;

2. If items clog the surface, it should be removed;

3. The filter surface damage is serious, you must replace the new filter or replace the new filter to re-install;

4. When the filter is installed, it is necessary to ensure good sealing with the presser side of the frame to prevent leakage of air.

5. Do not use heavy objects to impact the surface of the filter, can not force to pull the filter media surface;

6. Installation, should filter bag length direction perpendicular to the ground, to ensure that the air filter effect and increase the service life.

9. In effect bag filter replacement rules

1. In the rated air use conditions, 3-4 months that need to replace the filter

2. When the filter resistance reaches 400Pa or more, the filter must be replaced

3. If the filter is using a clean filter, replace the filter, you can use water or a solution containing neutral detergent rinse, dry, and then put up; up to allow cleaning twice, that is necessary Replace the new filter

4. If the dust concentration in the environment is large, the service life cycle will be reduced